- Manifolds require that multiple solenoid valves are configured as one manifold with the solenoid valves being 4-way three position.

- Manifolds design pressure of 175psig at 175F

- Continuous duty AC current solenoid valves

- Shock and vibration qualified

A long-term client of Huber was needing a custom solution for a class of vessels. The client had previously worked with Huber on other projects and were aware of Huber’s capabilities and excellence at providing superior solutions.

The client needed Huber to supply components, including manifolds, to control a ballast system: to help immerse the rudder, support the maneuverability of the vessel and also reduce the exposed hull surface. Because the ship continually uses fuel and water from its tanks leading to weight loss, the ballast operation helps in compensating for this loss.

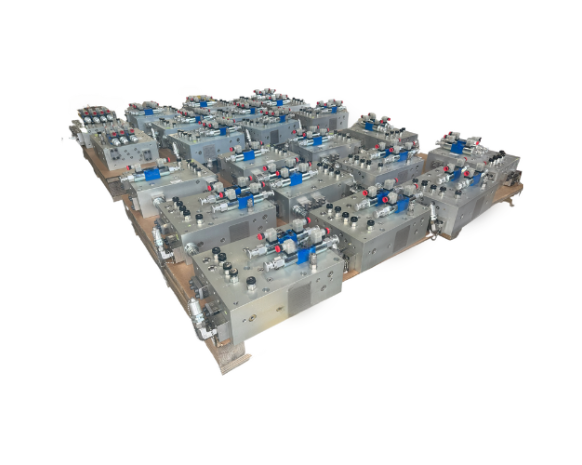

For this project, Huber supplied the 1-valve, 2-valve, 3-valve, and 4-valve station manifolds, which included the manifolds, valves, vessel connections, and all hardware.

The customer requested that the manifolds be as lightweight as possible, and so it was determined that they be made of 6061 aluminum. Also, the manifolds needed to pass shock and vibration testing, which again Huber was able to accomplish.

Huber successfully met the customers’ requirements for this project, supplying 28 custom manifolds.