SPECIFICATIONS

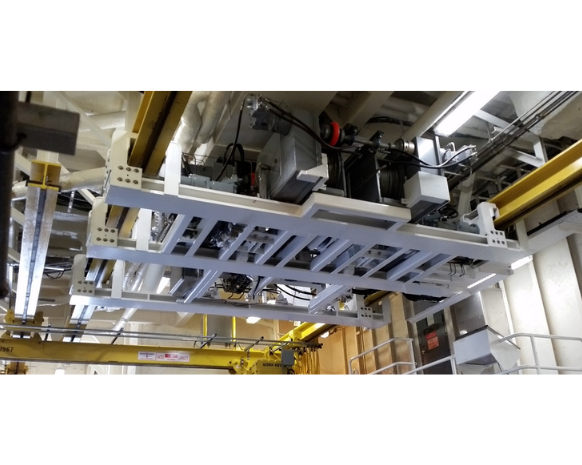

- Overhead trolley (moving forward & aft) with 4 custom winches

- Overhead cursor (moving with the trolley, but also up and down through the moon pool)

- Custom constant tension umbilical winch

- Separate Bridge Crane and Monorail Crane

- Centralized Hydraulic Power Unit

- PLC Control System with HMI Touchscreen I/O and Joy Stick Commands

- ABS Rules for Underwater Vessels, SysteABS Rules for Underwater Vessels, Systems, and Hyperbaric Facilities, and Hyperbaric Facilities

PROJECT DETAILS

Speed is often a performance factor for success, especially in military and commercial applications. In one recent SIT project, the client needed a dual speed launch and recovery (LAR) system with a safe working load up to 10,000 pounds, traveling swiftly at 30 feet per minute while the payload or work package was in air, but up to 300 feet per minute when it was in the water. The LAR system trolley and winches also needed to orient the underwater package from a completely horizontal position to a 45-degree pitch forward prior to lowering or raising the package through the moon pool.

The entire system needed to fit in the O2 level overhead hangar space of the vessel which was already in service. It would not be an easy feat; luckily, the client had a long-standing relationship with SIT, and knew they could trust the company to deliver quality work.

SIT would need to meet the stringent requirements for the trolley in terms of dynamic loading and cycle times. Since the package had to be lifted and lowered from the deck or through the moonpool, meaning it was walked forward and aft, nothing could be fixed to bulkheads, and with the manifolds and valves mounted to the trolley, hose and electrical cable tracks were necessary to support the movement. In addition, SIT ended up building custom I-beams to fit the strength requirements while operating the custom winch assembly with the trolley at any position along the support beams.

When completed, the work met or exceeded all requirements. Various tests were completed to prove the LAR system was able to operate per the Customer and Regulatory requirements. With this protected ship’s inboard system in place, the client was able to launch from inside the center portion of the vessel instead of a side or stern davit on the vessel deck. This provided less dynamic loading, an increased speed of launch and recovery, ensured the safety of the crew, and allowed operation in diverse environmental conditions without exposure to external conditions or concerns.