SPECIFICATIONS

- Primary Pressure Accumulation/Supply and Control Skid

- 5 Remote Swivel sub-panel assemblies

- 10 accumulators

- Designated accumulator logic manifold and filter logic manifold for each swivel section

- Manifolds are populated with 316SS cartridge assemblies specified for their given functional requirement

- Hydraulic circuitry machined internally, interconnecting the cartridge assemblies

PROJECT DETAILS

The customers’ existing systems have a large footprint and a significant amount of tubing creating numerous leak points over the course of installation and operation with limited redundancy and troubleshooting capabilities.

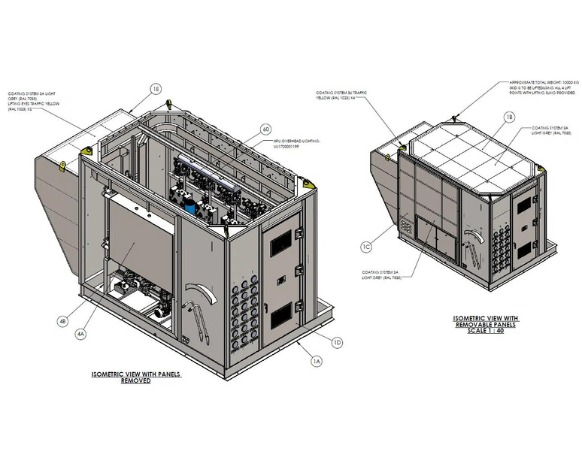

SIT helped the customer resolve their problem by creating a walk-in modular skid system utilizing a custom manifold system with cartridge valves. This eliminated 75% of tubing and leak points, increased isolation capability for trouble shooting with system redundance, decreased overall footprint, reduced future engineering costs with modular design along with operational maintenance cost with simple component replacement.

Extra consideration was given to modularizing the FBS for reduced future engineering and installation cost, maximizing overall system efficiency and performance while paying extra attention in reducing maintenance cost (including ease of component replacement for reduced down time and general maintenance). In conjunction with the above, additional measures were taken to reduce the total weight and footprint of the FBS and FBMP’s through integrated, high pressure hydraulic manifolds. This proven design method eliminates runs of interconnecting tubing cutting down on leak points, installation footprint, and maintenance costs by 75-80%. Operation and isolation for each swivel is easily identifiable as the manifold sets are segregated as individual control stations. In addition, all major functions are redundant. To replace any component, a segment can be isolated without shutdown and no incoming or outgoing tubing requires disconnection. This saves not only time in replacement of components but limits any down time and contamination ingress.