Supreme Integrated Technology, Inc. (SIT), through its SIT-Huber division, has built a reputation for providing state-of-the-art hydraulic power units (HPUs) and advanced solutions for the U.S. Navy, Coast Guard, Army, and Marine Corps. With over 20 years of experience in the industry, SIT-Huber continues to deliver innovative ballast hydraulic systems designed to meet stringent military requirements and ensure long-lasting, reliable performance.

This blog will dive into the specific requirements, history, and solutions that SIT-Huber has provided for the military and marine industries. If you’re looking for reliable, qualified, and field serviceable hydraulic systems for your naval vessels, SIT-Huber is the trusted name in the industry.

Key Requirements for Ballast Hydraulic Systems

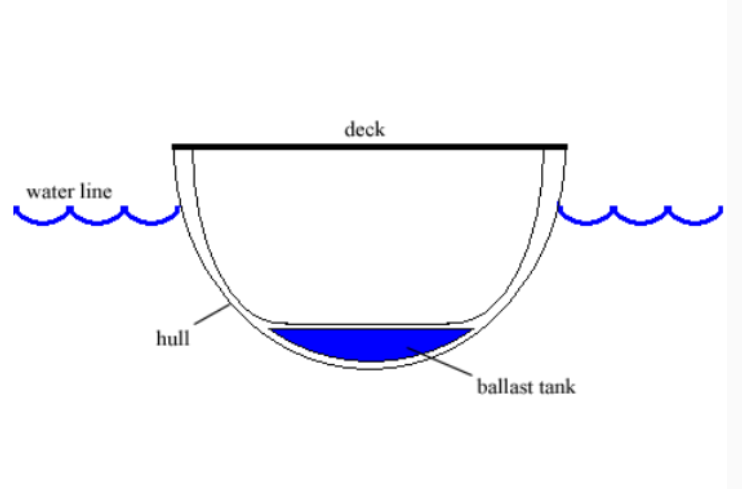

Ballast control systems are critical for the operation of military vessels. These systems manage the distribution of water to maintain a ship’s stability, ensuring optimal performance in both normal and emergency conditions. For military vessels, SIT-Huber developed a custom solution that met several important requirements:

- Rapid Operation: The ballast hydraulic system must be capable of opening and closing ballast sea valves in less than one minute. This rapid operation is essential for maintaining the ship’s stability during critical maneuvers or emergency situations.

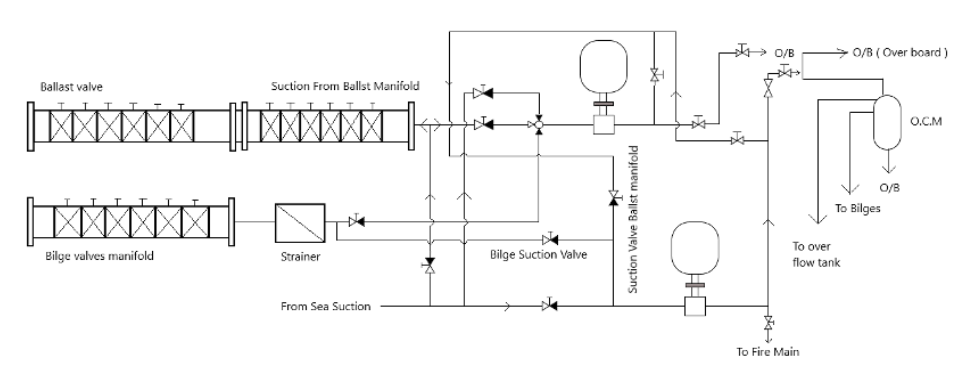

- System Components: The ballast system comprises a complex network of components that must work in harmony to deliver efficient performance. This includes:

- Hydraulic Power Units (HPUs)

- Hydraulic Reservoir Tanks

- Control Valve Manifolds

- Ringmain Isolation and Segregation Valves

- Military-Grade Qualification: All systems must be qualified to meet MIL-S-901D Shock and Vibration Specification standards, ensuring that the equipment can withstand the harsh conditions experienced by naval vessels during operations.

- Longevity and Maintainability: These systems are designed to be maintainable and field serviceable, ensuring they can be repaired and maintained throughout decades of service, minimizing downtime and extending the system’s lifespan.

These stringent requirements highlight the complexity and precision necessary to design systems that can perform consistently under demanding conditions.

A Strong Legacy of Hydraulic Power Unit Innovation

SIT-Huber has a rich history in the manufacturing and engineering of hydraulic power units (HPUs). Over the past two decades, the company has been at the forefront of developing cutting-edge designs for sea-based platforms used by the military.

SIT-Huber’s legacy began in the 1990s, when the company first started delivering hydraulic solutions to the Navy and other military branches. Since then, SIT-Huber has become a trusted partner for the military, providing networked and survivable platforms that are essential for modern sea-based operations.

These platforms are built to withstand the harshest environments and perform reliably in critical situations. The U.S. Navy and other military branches continue to rely on SIT-Huber’s hydraulic systems to maintain vessel stability and operational efficiency in both peacetime and combat scenarios.

Delivering a Custom Ballast Hydraulic System for the Navy

When tasked with designing and building a custom ballast hydraulic system for a naval vessel, SIT-Huber leveraged its vast experience in hydraulics and military solutions. The team worked closely with the customer to meet all the specified criteria, ensuring that the system would perform efficiently in a military setting.

Here’s a breakdown of the process and the solution provided:

Custom Design to Meet Military Requirements

SIT-Huber’s engineers worked with the provided military specifications to develop a ballast control system capable of opening and closing sea valves in under one minute. This fast actuation was essential for the system to meet the Navy’s strict operational requirements.

To achieve this, SIT-Huber used custom hydraulic components, including HPUs, hydraulic reservoirs, control valve manifolds, and isolation valves. The system was designed to be fully maintainable, allowing for easy field servicing to ensure longevity throughout the vessel’s lifespan.

Collaboration with a Broad Supplier Base

SIT-Huber collaborated with over 100 vendors to source the necessary components for the ballast hydraulic system. The company’s status as an OEM (Original Equipment Manufacturer) allowed it to work effectively with these suppliers, ensuring cost-effective sourcing and on-time delivery of parts.

This extensive supplier network also helps SIT-Huber overcome challenges related to parts obsolescence, ensuring that the company can continue delivering system components for years to come. This flexibility is critical for ensuring that naval vessels remain operational, even as certain parts become obsolete over time.

State-of-the-Art Fabrication and Assembly

The fabrication and assembly of the ballast hydraulic system components were conducted at SIT’s corporate headquarters and fabrication center in New Orleans, Louisiana. All welding, inspection, painting, and assembly were carried out by certified professionals who meet applicable military and commercial standards.

Once the components were fabricated, the system’s final assembly and testing (FAT) took place at SIT’s assembly facility in Houston, Texas. SIT-Huber ensured that all components were built and tested to meet NAVSEA and Military standards, guaranteeing the highest levels of quality and reliability.

Meeting Longevity and Maintainability Standards

One of the core design philosophies behind SIT-Huber’s systems is ensuring long-term maintainability. The ballast control system was designed with easy access to critical components, allowing for field servicing and maintenance throughout the system’s life cycle.

This long-term approach ensures that the Navy can rely on SIT-Huber’s systems for decades, with minimal downtime and repair needs. As military technology evolves, SIT-Huber remains committed to providing systems that are adaptable and maintainable, ensuring continued operational success for the Navy.

The Future of Hydraulic Power Units with SIT-Huber

SIT-Huber’s commitment to excellence extends beyond the completion of individual projects. As the Navy and other branches of the military continue to evolve, SIT-Huber remains focused on developing new, innovative solutions to meet their ever-changing needs.

SIT-Huber’s legacy of providing turn-key hydraulic systems has solidified its position as a leader in the military and marine industries. The company’s history began in the 1990s, and it has continued to deliver integrated hydraulic systems that meet the highest standards of quality and performance.

As part of Supreme Integrated Technology, Inc., SIT-Huber continues to offer the same turn-key hydraulic system design packages that Huber, Inc. was known for before its acquisition in 2013. SIT-Huber now serves a broader range of industries, including industrial, marine, and jacking systems, in addition to continuing its work with military hydraulic systems.

Conclusion: Trust SIT-Huber for Reliable Hydraulic Solutions

For over 20 years, SIT-Huber has been a trusted provider of hydraulic power units and ballast control systems for the military and marine industries. With a proven track record of delivering innovative solutions that meet strict military standards, SIT-Huber is well-positioned to continue providing these critical systems for decades to come.

Whether you’re looking for a ballast hydraulic system, a custom hydraulic power unit, or another hydraulic solution for your vessel, SIT-Huber has the expertise and resources to deliver a reliable and cost-effective solution. From design and fabrication to long-term serviceability, SIT-Huber ensures that your systems are built to last.

To learn more about how SIT-Huber can help you with your next project, contact us today or visit our website at www.supremeintegratedtechnology.com.