The Comprehensive Guide to Pneumatically Operated High-Pressure Manifolds

Pneumatically operated high-pressure manifolds are less commonly used compared to their manual and hydraulic counterparts. Despite their limited prevalence, they offer unique advantages in safety, operational efficiency, and environmental impact. This article delves into the benefits and challenges of these systems, helping you understand their role in manifold operation and control.

What Are Pneumatically Operated High-Pressure Manifolds?

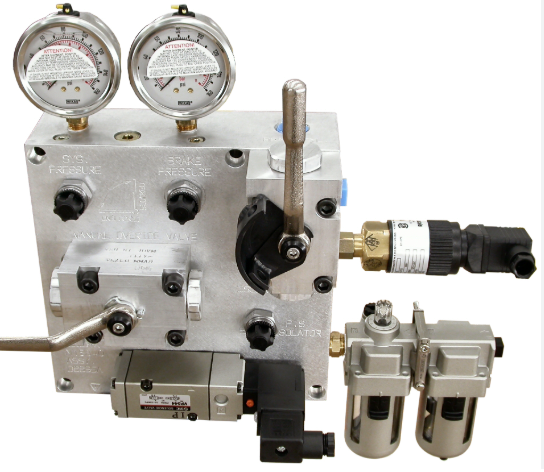

These manifolds function by using a pneumatic control panel equipped with directional control valves. Airflow is directed to valve-actuator assemblies, enabling remote operation. Unlike manually operated systems, pneumatic manifolds eliminate the need for handwheels and gear operators, reducing physical labor and increasing safety.

Key Features of Pneumatic Systems

- Remote Operation: Panels are situated away from high-pressure zones, ensuring a safer environment.

- Air-Powered Technology: Uses compressed air, making it eco-friendly and cost-efficient.

- Automation-Friendly: Simplifies complex operations with user-friendly controls like levers and push buttons.

Advantages of Pneumatically Operated Manifolds

1. Hazardous Area Certification

Pneumatically operated manifolds are inherently safer in explosive or flammable environments. Since they don’t rely on electricity, the risk of auto-ignition from nearby gases or dust is virtually eliminated.

2. Environmentally Friendly

These systems are “green” by design. The only emissions originate from the air compressor, making them a sustainable choice compared to hydraulic systems.

3. Ease of Use

Operators can control valves with simple push buttons or manual handles, streamlining the process and reducing the risk of human error.

4. Lower Labor Costs

Automation significantly decreases manpower requirements, lowering overall operational costs.

5. Minimal Maintenance

Pneumatic systems have fewer moving parts, reducing maintenance needs. Regular service of regulator, filter, and lubricator assemblies ensures extended service life and lowers the total cost of ownership.

Challenges of Pneumatically Operated Manifolds

1. Low Power Density

Pneumatic systems operate at 80–120 PSI, requiring larger actuators to achieve the high torque needed for 10,000 or 15,000 PSI plug valves.

2. Limited Operator Mobility

Control panels remain tethered to the manifold, restricting on-site mobility for operators.

3. Increased Footprint

The pneumatic equipment, including compressors and conductors, occupies more space and adds weight to the worksite, posing logistical challenges.

4. Extended Startup Time

Connecting the manifold to the pneumatic control panel requires additional time, potentially delaying operations.

5. Higher Installation Costs

The upfront capital expenditure for pneumatic systems is greater compared to manually operated manifolds due to the need for specialized equipment.

Why Choose Pneumatically Operated Manifolds?

Despite their limitations, pneumatically operated manifolds are an excellent choice for sites with explosive risks or where automation is prioritized. They provide:

- Reliable performance.

- Enhanced operator safety through remote operation.

- Reduced environmental impact, aligning with sustainable practices.

By understanding their unique features, operators can decide if these systems align with their project requirements and operational goals.

Conclusion

Pneumatically operated high-pressure manifolds offer a balanced mix of safety, efficiency, and eco-friendliness, making them a valuable addition to manifold operation technologies. While they come with challenges like increased footprint and power density limitations, their benefits often outweigh these drawbacks in specific applications.

Choosing the right manifold system requires careful consideration of site conditions, operational needs, and long-term costs. With their reliable performance and environmental advantages, pneumatic systems continue to be a solid option for high-pressure applications.