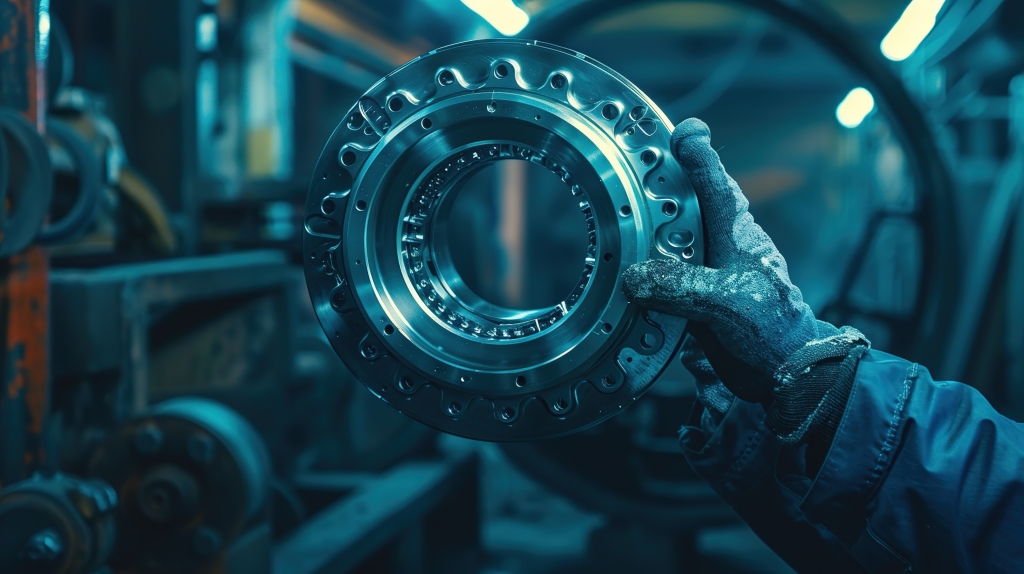

Learn how to identify and troubleshoot your hydraulic pump in four simple steps.

Hydraulic pumps are the heart of any industrial or mobile hydraulic system. Ensuring their optimal functionality is paramount for the efficiency and longevity of one’s machinery. This guide delves deep into common hydraulic pump problems, providing detailed troubleshooting steps to help maintain peak performance.

Table of Contents

- Introduction to Hydraulic Pumps

- Identifying Common Hydraulic Pump Problems

- Detailed Troubleshooting Techniques

- Preventative Maintenance Tips

- Conclusion

Introduction to Hydraulic Pumps

Hydraulic pumps convert mechanical energy into hydraulic energy, facilitating the movement of fluid within a hydraulic system. Understanding the basics of how these pumps operate is essential for diagnosing and troubleshooting issues effectively.

Identifying Common Hydraulic Pump Problems

1. Noisy Operation

Noise in hydraulic pumps can be indicative of several issues, including aeration, cavitation, and mechanical wear. Excessive noise often points to problems that could lead to more severe damage if left unaddressed.

2. Overheating

Overheating is a common issue that can result from excessive friction, poor lubrication, or insufficient cooling. It can lead to significant damage if not promptly resolved.

3. Reduced Flow Rate

A noticeable drop in the flow rate can affect the efficiency of the entire hydraulic system. Internal leaks, worn components, or blockages within the system may cause this problem.

4. Fluid Contamination

Contaminated hydraulic fluid can cause severe damage to the pump and other components. It is often caused by poor maintenance practices or environmental factors.

Detailed Troubleshooting Techniques

1. Addressing Noisy Operation

- Aeration: Check for air leaks in the suction line or fittings. Ensure all connections are tight and the seals are intact.

- Cavitation: Verify that the pump is not drawing in air or vapor. Ensure the suction line is free of blockages and has an adequate fluid level.

- Mechanical Wear: Inspect the pump for signs of wear, including worn bearings or misaligned components. Replace any damaged parts.

2. Solving Overheating Issues

- Lubrication: Ensure the hydraulic fluid is of the correct type and viscosity. Regularly check fluid levels and top off as necessary.

- Cooling System: Inspect the cooling system for blockages or malfunctions. Clean or replace cooling elements as needed.

- Friction Reduction: Lubricate moving parts adequately to minimize friction. Consider using high-quality lubricants designed for hydraulic systems.

3. Improving Flow Rate

- Internal Leaks: Inspect the pump and associated components for internal leaks. Replace worn seals and gaskets.

- Component Wear: Check for worn or damaged components, such as pistons or valves. Replace any faulty parts.

- Blockages: Clear any blockages in the hydraulic lines or filters. Regularly clean or replace filters to prevent future blockages.

4. Preventing Fluid Contamination

- Regular Maintenance: Implement a regular maintenance schedule to check and replace hydraulic fluid. Use filters to trap contaminants.

- Environmental Controls: Protect the hydraulic system from environmental contaminants, such as dust or water. Use protective covers and ensure proper storage.

- Fluid Quality: Use high-quality hydraulic fluid from reputable suppliers. Avoid mixing different types of fluids.

Preventative Maintenance Tips

- Routine Inspections: The hydraulic pump and associated components are regularly inspected for signs of wear, leaks, or other issues.

- Scheduled Fluid Changes: Change the hydraulic fluid at intervals recommended by the manufacturer. Monitor fluid condition regularly.

- Component Replacement: Replace worn or damaged components promptly to prevent further damage to the system.

- Clean Environment: Maintain a clean environment around the hydraulic system to minimize contamination risks.

Conclusion

Proactively addressing common hydraulic pump problems is essential for maintaining the efficiency and longevity of hydraulic systems. By understanding the root causes of issues and implementing effective troubleshooting techniques, we can ensure reliable operation and minimize downtime. Regular maintenance and prompt repairs are key to preventing severe damage and costly repairs in the future.

As your single-source solution provider for hydraulic and electric-powered movable structures, SIT is ready to help with your application needs. Have questions? Contact us.