A Step-by-Step Guide to Sizing a Hydraulic Power Unit (HPU)

Hydraulic Power Units (HPUs) play a vital role in supplying fluid power to hydraulic actuators, including cylinders and motors. Selecting and designing the right HPU for your application is essential for ensuring optimal performance. This guide outlines the critical steps to properly size and configure an HPU, considering factors such as pressure, flow, pump type, and system design.

Step 1: Understand the Application Requirements

Before sizing a hydraulic power unit, the first step is to fully understand the application’s needs. The requirements of the hydraulic actuators (cylinders and motors) will dictate the maximum working flow and pressure.

Defining Maximum Flow

To calculate the required flow, determine the number and types of cylinders and motors that will operate simultaneously. Flow depends on the speed at which these components must function.

Defining Pressure

Pressure is calculated based on the force necessary for each actuator to perform its tasks. This can be determined using standard hydraulic formulas.

Size Constraints

The available space for the HPU’s installation may limit the size of the components, reservoir, and other system parts. Make sure the design aligns with the space limitations of your application.

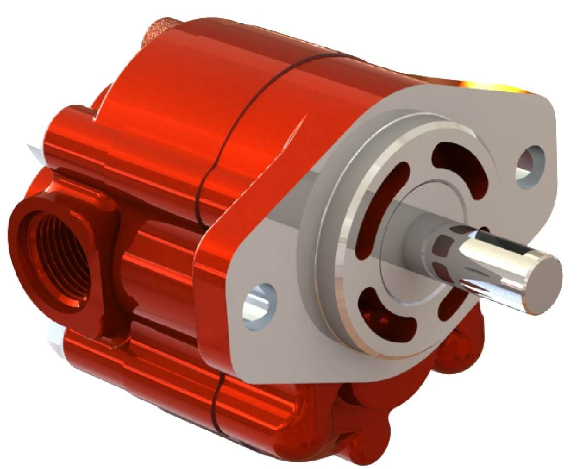

Step 2: Selecting the Right Pump

Choosing the right pump is crucial for the efficient operation of the hydraulic system. Multiple types of pumps are available, each offering different advantages.

Types of Hydraulic Pumps

- Gear Pumps: These are the most cost-effective and require less maintenance. However, they may not meet the demands for high pressure and speed.

- Piston Pumps: These are designed for high-pressure applications but are more expensive and require more maintenance.

- Bent Axis Pumps: These pumps offer versatility in flow and pressure but come at a higher cost.

The type of pump you select will depend on your flow and pressure requirements, as well as any size constraints.

Step 3: Configure the Pump Placement

Proper pump placement is another critical factor in designing your HPU system.

Pump Configuration Options

- Mounted Near the Reservoir: This allows easier maintenance access but requires the pump to lift the fluid, which can complicate cleaning.

- Mounted Below the Tank: This reduces suction lift, but space constraints may limit this option.

- Mounted Alongside the Tank: Offers balanced placement but requires careful consideration of fluid movement and maintenance access.

Step 4: Design the Hydraulic Reservoir

A properly designed reservoir is essential for the overall efficiency of the HPU. Industry standard ISO 4413 provides guidance on designing hydraulic reservoirs.

Reservoir Functions

- Heat Dissipation: The tank must dissipate heat generated by the system during operation.

- Fluid Storage: It should hold the necessary amount of fluid while allowing for thermal expansion.

- Air and Contaminant Separation: Ensure adequate separation between the incoming fluid and pump intake to allow trapped air to escape and contaminants to settle.

The size of the reservoir is generally 3-5 times the per-minute flow rate.

Step 5: Install a Pressure Relief Valve

A pressure relief valve is critical to prevent overpressure in the system, which could lead to damage or inefficiency.

Importance of Pressure Relief Valves

The relief valve allows fluid to return to the tank when the system does not need the full pump capacity, preventing overheating and energy waste. Selecting the right size of the pump and valve ensures that the system runs efficiently without the valve constantly operating.

Step 6: Ensure Proper Filtration

Clean fluid is the lifeblood of any hydraulic system. Implementing a filtration system within your HPU is vital to maintain its performance and longevity.

Filtration Options

- Pressure-Side Filtration: Installed on the pressure side of the pump to prevent contamination throughout the system. However, these filters must withstand the high pressure and contamination buildup, which can make them more complex.

- Return-Line Filtration: Positioned on the return side to keep contaminants from entering the reservoir. This option involves lower pressure but still effectively protects the system.

Conclusion: A Complete Solution for HPU Design

These steps provide a solid foundation for selecting and designing the ideal hydraulic power unit for your application. From understanding flow and pressure requirements to ensuring proper pump selection and filtration, these considerations will help ensure optimal system performance.

For more information or help with your next hydraulic project, contact Supreme Integrated Technology. We offer custom-designed HPUs for a wide variety of industries, including military, oil & gas, marine, and civil engineering.