The Grand Bayou Floodgate is a critical infrastructure project that plays a significant role in the Morganza to the Gulf Hurricane Protection System. This massive system is designed to shield vulnerable communities and ecosystems along the Louisiana coast from the devastating effects of hurricanes and storm surges. As climate change continues to increase the frequency and severity of storms, robust flood protection infrastructure like the Grand Bayou Floodgate is more crucial than ever.

In this article, we’ll explore the Grand Bayou Floodgate’s importance, its role in the broader Morganza to the Gulf system, and how Supreme Integrated Technology (SIT) is contributing to the construction and operation of this essential flood defense.

1. The Need for Hurricane Protection in Coastal Louisiana

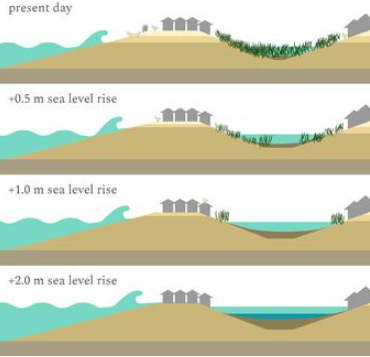

Coastal Louisiana is one of the most storm-vulnerable regions in the United States. Situated along the Gulf of Mexico, this area has experienced numerous powerful hurricanes over the decades, including Katrina, Rita, and Ida. The combination of rising sea levels, land subsidence, and the region’s intricate network of wetlands and waterways makes it particularly susceptible to storm surge flooding.

Why the Morganza to the Gulf System Matters

The Morganza to the Gulf Hurricane Protection System is a comprehensive effort to reduce the risk of storm surge flooding across the Terrebonne and Lafourche Parishes. This vast network of levees, floodgates, and pumping stations aims to safeguard homes, businesses, and critical infrastructure from the impacts of major storms. One of the standout features of this system is the Grand Bayou Floodgate.

2. What is the Grand Bayou Floodgate?

The Grand Bayou Floodgate is a vital structure within the Morganza to the Gulf system. It serves as both a defensive barrier and a key point of water control in the region. The floodgate spans Grand Bayou, a critical waterway that connects inland water systems to the Gulf of Mexico.

Key Features of the Floodgate

- Storm Surge Defense: During hurricanes and storm surges, the Grand Bayou Floodgate can be closed to block rising waters from flooding inland areas.

- Water Flow Management: In non-storm conditions, the floodgate remains open to allow for the natural flow of water between the bayou and the Gulf, maintaining the ecological balance of the area.

- Advanced Hydraulic Technology: The floodgate is equipped with cutting-edge hydraulic systems to ensure smooth operation during critical moments, such as during the approach of a hurricane.

3. Supreme Integrated Technology’s Role in the Project

Supreme Integrated Technology (SIT) has been a major contributor to the success of the Grand Bayou Floodgate project. SIT specializes in providing advanced hydraulic and motion control solutions for large-scale infrastructure projects like this one. Their expertise ensures that the floodgate functions reliably under pressure, especially during hurricane events when the system is most needed.

SIT’s Hydraulic and Control Systems

SIT’s involvement in the Grand Bayou Floodgate includes the design and installation of custom hydraulic systems that operate the floodgate’s massive gates. These systems are critical for allowing the floodgate to open and close efficiently, ensuring that it can quickly respond to changing water levels.

- Precision Control: SIT’s hydraulic systems provide precise control over the movement of the floodgate, ensuring it can be opened or closed in response to real-time data about water levels and storm conditions.

- Reliability Under Pressure: During a hurricane, the floodgate must perform flawlessly under extreme conditions. SIT’s hydraulic technology is designed to withstand high pressure and provide dependable operation even during the most severe storms.

4. The Importance of Floodgates in Coastal Protection

Floodgates like the one at Grand Bayou are critical components of coastal protection systems. They provide a controlled way to manage water flow and prevent flooding in vulnerable areas. The ability to close off key waterways during storm events is crucial for minimizing damage to homes, businesses, and natural habitats.

How Floodgates Work

Floodgates are large, reinforced barriers that can be opened or closed depending on the situation. During normal weather, they remain open to allow natural water flow. However, when storm surges threaten to inundate coastal areas, these gates can be closed to block rising water from entering inland regions.

The Grand Bayou Floodgate is part of a broader network of floodgates within the Morganza to the Gulf system, each playing a role in protecting the coastline from the effects of hurricanes and other severe weather events.

5. The Broader Impact of the Morganza to the Gulf System

The Morganza to the Gulf Hurricane Protection System is not just about protecting property—it’s about preserving a way of life for the people of coastal Louisiana. The region’s economy is heavily dependent on industries such as fishing, oil, and gas production, and tourism, all of which are vulnerable to storm damage.

Economic and Ecological Benefits

- Economic Protection: By preventing flooding and storm surge damage, the Morganza to the Gulf system helps protect billions of dollars in infrastructure and economic activity.

- Wetland Preservation: The levees and floodgates also play a role in preserving Louisiana’s wetlands, which act as natural buffers against storms and provide habitats for diverse wildlife.

The Grand Bayou Floodgate, as part of this larger system, is essential in helping sustain the local economy and protecting the ecological health of the region.

6. The Future of Coastal Protection

As climate change accelerates, the need for advanced coastal protection systems will continue to grow. Rising sea levels and more frequent intense hurricanes mean that projects like the Grand Bayou Floodgate are becoming increasingly important.

Innovations in Flood Defense Technology

- Improved Hydraulic Systems: As hydraulic technology continues to advance, future floodgates may become even more efficient and reliable, allowing for faster response times and better integration with real-time weather data.

- Sustainability Considerations: New materials and designs may help make flood protection infrastructure more sustainable, reducing environmental impact while providing essential defense against storms.

SIT remains at the forefront of these developments, working on next-generation hydraulic systems and control solutions to meet the challenges of the future.

Conclusion

The Grand Bayou Floodgate is a key element in the Morganza to the Gulf Hurricane Protection System, providing vital defense against hurricanes and storm surges for coastal Louisiana. With the help of Supreme Integrated Technology’s advanced hydraulic systems, the floodgate is able to operate efficiently, protecting both the local population and the environment.

As climate change continues to pose new challenges, infrastructure projects like the Grand Bayou Floodgate will be crucial for safeguarding communities and preserving the delicate ecosystems of the Louisiana coast. With continued innovation and investment in flood protection technology, we can build a more resilient future for storm-prone areas.