SPECIFICATIONS

- Test Stand: 108” x 39 1/8” x 76 5/8”

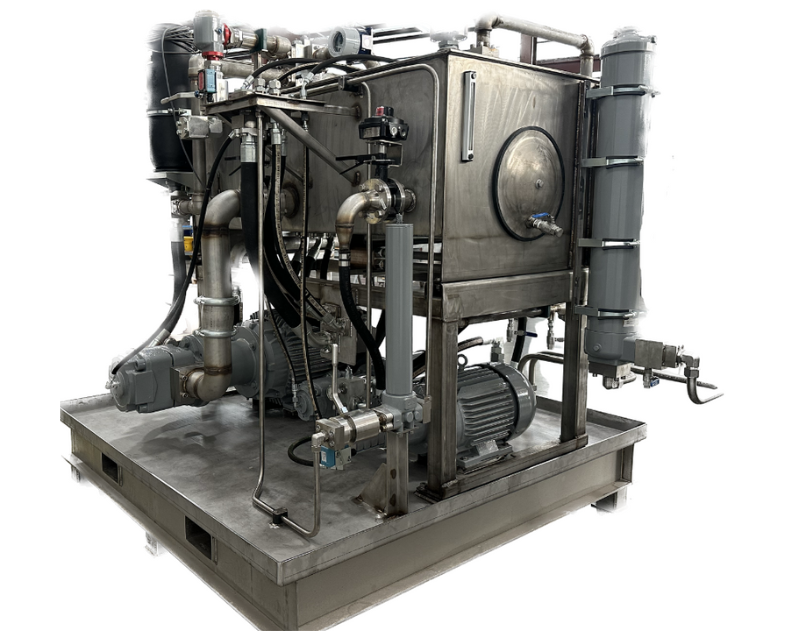

- HPU: 93 3/8” x 77” x 90 5/16”

- 200 PSI working pressure: 3500 PSI proof pressure

- 100 GPM max flow: Separate low flow circuit up to 10GPM for increased resolution at lower flowrates

PROJECT DETAILS

GCC (sister company of SIT) has fostered a 25+ year partnership with its customer, marked by GCC’s unwavering support and expertise. Specializing in custom Test Stands and HPU’s, the collaboration extends to crafting systems, using skydrol hydraulic fluid for its fire resistance and ability to endure high temperatures/pressures despite its corrosive nature.

In a joint effort, SIT and GCC delivered to the customer a unique test stand and HPU, complete with electrical panel assemblies for control. Specifically designed for production testing of jet fuel filter housings, the system ensures a leak-free and defect-free assembly by conducting pressure tests and measuring pressure drop at a flow rate of 100 GPM.

What sets this project apart is its use of “Jet Fuel” as the testing medium, with an extremely low flash point of 100 degrees. To address safety concerns, both the test stand and HPU are explosion-proof, featuring enclosed and nitrogen-purged electrical control panels and hydraulic control manifolds. High-frequency response control valves enable closed-loop pressure or flow control, adjustable electronically via an HMI mounted to the test stand.

Adding to its efficiency, the system allows operators to input parameters via the HMI, electronically delivering pressure or flow as needed. Presets for specific test articles further streamline the process with a simple button push.

Remarkably, the test stand and HPU, located in different places, are seamlessly connected through an ethernet fieldbus. Unlike traditional installations requiring extensive cable runs, this solution allows for pre-wiring and testing completed at the SIT facility. Upon delivery, the customer merely connects a single ethernet cable between the two assemblies, simplifying the installation process significantly. Similar to the illustration below, the customer’s sole responsibility is to connect the green cable, ensuring a hassle-free setup.