- Total Assembly Weight – 10,084 lbs.

- Height – 85” (~7.08ft)

- Width – 38” – (~3.16ft)

- Operating Pressure – 2500psi

- Designed and Tested to API 6D

In the dynamic world of offshore drilling, the reliability of equipment is paramount. The performance of critical components can make or break operations, affecting both its safety and efficiency. For this particular project, the existing assembly was stuck in a partially open position and so SIT was brought in to evaluate all existing documentation and assembly performance.

The riser valve/actuator assembly is located on a Semi-Submersible offshore drilling platform, serving as an isolation device for the temporary extension of the marine drilling risers from the blow out preventer (BOP). The original valve was monogrammed per API 6D requirements when implemented almost 20 years ago. Since then the API rules have been updated to not include an assembly’s bore size, so the updated assembly could not be monogrammed, but accepted as a like-for-like valve replacement.

SIT reevaluated all valve, drive train and actuator performance calculations from its customer. Based on the original system pressure of 7500psi it was determined that the assembly was specified incorrectly. However, after further system line pressure evaluations it was discovered that the system had not been operated in excess of 550psi, which supported the historical performance. Once this discovery was included into the actual performance requirements, the valve/actuator assembly had an overall safety factor of over 25:1. Therefore, the customer is currently reevaluating the system pressure requirements to help right size the actuator to help lower weight, repair, and replacement costs.

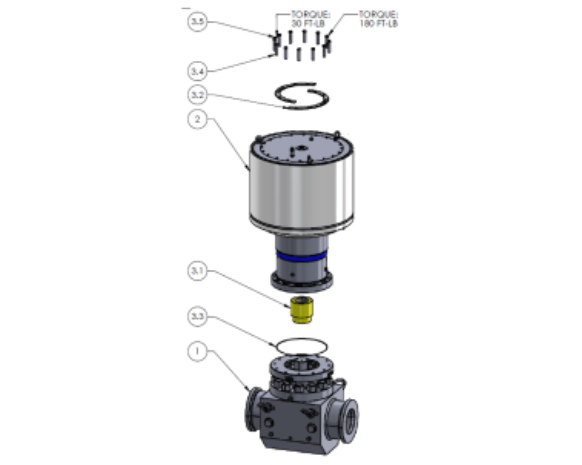

SIT ended up providing an Emerson Dantorque fail-safe actuator, Cornerstone metal seated 8”/10K trunnion ball valve, assembly performance calculations, API 6D specification review, actuator torque testing, FAT, and supporting documentation (3D models, testing, installation procedure, etc) for this specific project.