SPECIFICATIONS

- 28 ft. long x 7 ft. tall x 16 ft. wide

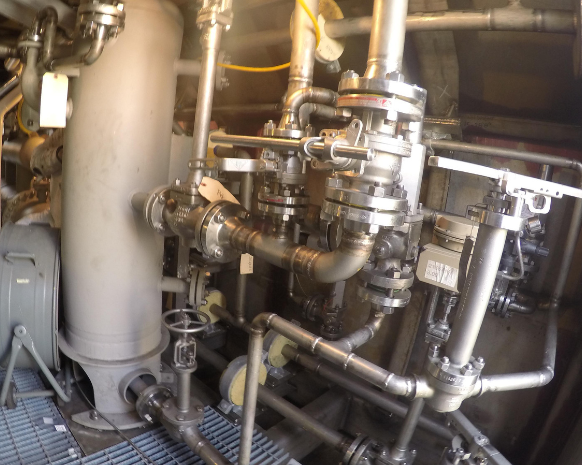

- 316 stainless steel construction

- 316 stainless steel piping

- 316 stainless steel electrical panels

- 82,000 lb. total weight

- Cryogenic weld procedures

- Welds -100% visual inspection (VT) and x-ray or radiological testing (RT)

- Pump room designed to be airtight up to 2 PSIG of pressure distributed on the entire internal structure

- Det Norske Veritas (DNV)

PROJECT DETAILS

Working with LNG combustion yields incredibly high pressures, yet vessel safety remains of the utmost importance. In one recent case, a first-in-class biofuel hybrid vessel needed an internal LNG pumphouse, which was to be to be put on two barges that were to operate along the Gulf Coast.

Among the other challenges, having the pumphouse nested so deeply inside the vessel required a secondary barrier able to withstand 2 PSI, or all the piping within the pumphouse had to be double-walled.

A high level of engineering expertise would be required to complete the work on this unique project. The client gave the work to SIT, whose expertise, few in the industry could match for this type of project.

Many steps were involved to complete the pumphouse. Almost 80 percent of the work was fabrication and assembly, involving some high premium materials and stringent welding requirements. All welds had to pass x-ray tests, and cryogenic thermal isolation blocks had to be mounted under the skid. SIT provided the proprietary calculations and design for the external barrier of the pumphouse ensuring it was able to withstand 2 PSI of force due to any leaks or explosions inside of the pumphouse.

In the end, the client received a pumphouse that was the first of its kind. With the pumphouse delivered on time and within budget, the client was able to quickly qualify the vessel to related regulations assuring it of safe operations.

Project Highlights:

- Cryogenic weld procedures

- Welds -100% visual inspection (VT) and x-ray or radiological testing (RT)

- Pump room designed to be airtight up to 2 PSIG of pressure distributed on the entire internal structure

Certifications:

- Det Norske Veritas (DNV)

- U. S. Coast Guard