SPECIFICATIONS

- ABS Rules for Building and Classing Steel Vessels

- ABS Approved Welders and Weld Procedures

- ABS Design Submittals, Test Plans, and Quality Data

PROJECT DETAILS

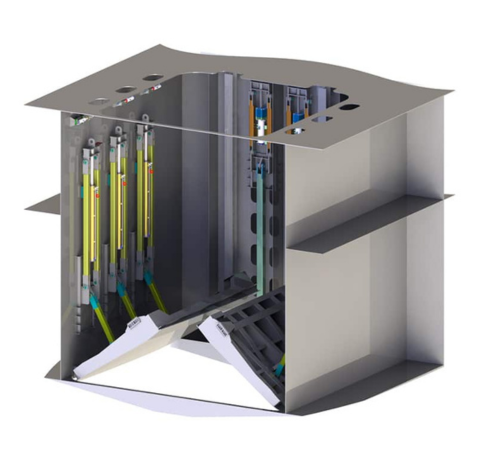

Precision is always possible given the right expertise. To close off the opening in the hull of the ship, a client required a set of door halves that sealed an 18’ by 18’ moon pool door opening. These doors needed to cycle quickly and cause no obstruction outside of the ship’s hull or within the moon pool. All cylinders had to be retracted, with the rods protected from the environment while in the sea going arrangement.

One main challenge of the project was that the moon pool door had to be built with continuity to the complex curvatures of the hull’s keel area. To complicate matters further, installation and integration of all components needed to be completed in a rather confined space.

Knowing that the project would require a high degree of expertise, the client turned to the people it has trusted for more than 20 years: SIT. Completing the project would require creative engineering solutions based on manufacturing experience and expertise. These are traits that SIT is able to provide through its in-house talent. Dutifully, SIT provided all the engineering design drawings, the calculation package submittals, and finite element analyses of the doors and provided supporting interface designs, installation instructions, and test plans to the shipyard.

Not only was SIT able to deliver the moon pool doors on time and under budget, the system performed even faster than the requirements of the customer.