SPECIFICATIONS

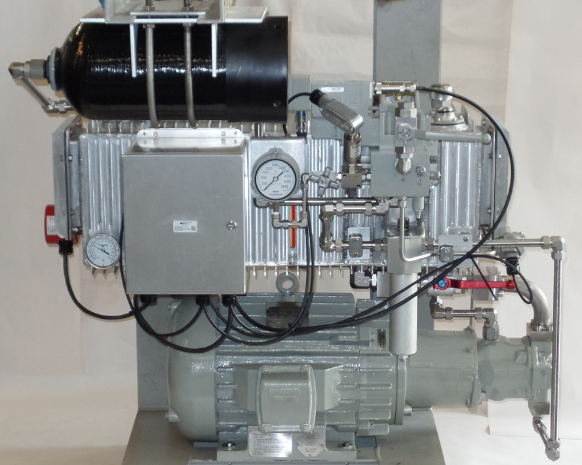

- Aluminum reservoir

- Custom fins to dissipate heat (reduced size of reservoir)

- Motor/pump group

- Air bladder

- NAVSEA

- NAVAIR

- MIL standards

PROJECT DETAILS

Recently, a defense client was looking to improve the design of their vessels, with a need to lighten the hydraulic power units used for onboard operations.

Most vendors wanted too much money to complete the lengthy project, and few had the track record that the client was seeking. But since SIT had been involved in the research and development phase of the project which had performed so well, the client brought them onboard to finish the later stages.

A main challenge was that the HPU would need to both perform at a very high temperature as well as meet lofty standards for controllability. Rare parts were also needed; for instance, there were only one or two valve manufacturers in the world that could supply the necessary valves to meet weight, speed, control, and temperature requirements.

It took a lot of research to figure out how to achieve the high-performance criteria for the HPU, while maintaining a light weight assembly. As SIT modeled the entire reservoir and circuitry, analyses were conducted for heat dissipation, flow circulation, and pressure loss. The end results optimized weight savings while garnishing all operational performance parameters.

Eventually, SIT was able to deliver the desired HPU within budget by leveraging their supply chain associations. SIT’s relationships with vendors allowed them to bring down costs for the client more than any other competing supplier, and deliver the finished HPU within project timelines