Understanding CDUs for Liquid Cooling in High-Density Data Centers

As the demand for real-time digital services, AI computing, and cloud infrastructure surges, data centers are under immense pressure to deliver continuous performance without thermal compromise. Central to this mission are Coolant Distribution Units (CDUs) — engineered systems that bridge the gap between precision cooling at the rack level and building-widely chilled water systems.

What Is a Coolant Distribution Unit (CDU)?

A Coolant Distribution Unit is a modular, high-efficiency thermal transfer system designed to manage the flow, temperature, and cleanliness of coolant between the IT cooling loop and the facility water supply. By isolating the IT-side loop from the facility’s variable water conditions, CDUs ensure stable, reliable heat rejection essential for modern computing environments.

The Role of CDUs in Modern Data Center Infrastructure

CDUs play a pivotal role in enabling liquid cooling architectures — such as direct-to-chip, rear door heat exchanger (RDHx), and immersion cooling systems — which are increasingly necessary as rack power densities exceed 30–50 kW. By supporting these advanced technologies, CDUs ensure:

- Precise coolant temperature regulation

- Continuous flow to mission-critical components

- Thermal isolation and contamination protection

- Centralized monitoring and operational control

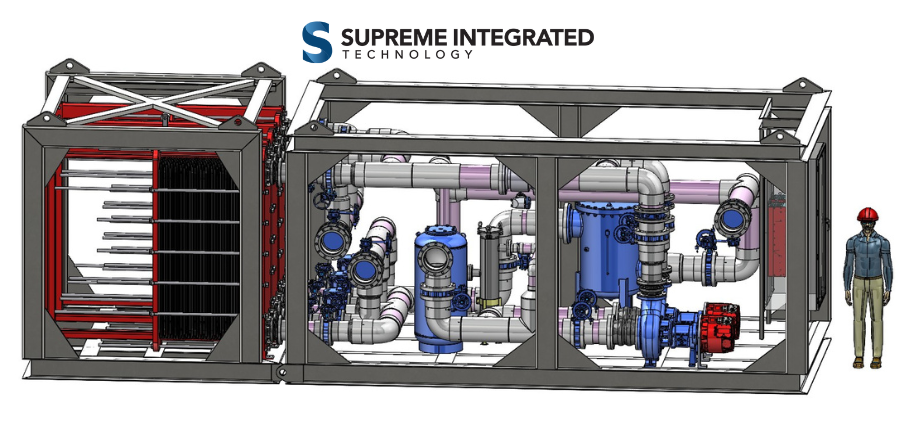

SIT: A Leading CDU Provider Powering the Future of Data Center Cooling

Supreme Integrated Technology (SIT), in collaboration with sister company Hydraquip, Inc., recently engineered a centralized single-phase cooling distribution skid for a next-generation hyperscale data center. This high-capacity CDU system reflects SIT’s expertise in designing and delivering turnkey thermal management solutions tailored to the evolving demands of global digital infrastructure.

Highlights from the SIT Project:

- Dual 125 HP Pump-Motor Groups

Equipped with Danfoss VFDs and Editron high-efficiency motors, these pumps deliver precise flow control with full system redundancy to ensure uninterrupted operation. - Custom Heat Exchangers

Purpose-built to dissipate heat from high-density server racks, supporting thermal stability across critical workloads. - Side-Stream Injection Filtration

Enables continuous particulate removal and fluid cleanliness, extending equipment life and reducing service intervals. - Advanced Flow Monitoring

Integrated flow meters provide real-time performance data for predictive maintenance and operational transparency. - High-Performance Valves with Electric Actuation

8″ HPBVs with electric actuators ensure automated control of critical coolant paths for optimal system response. - Manual Redundancy Valves

A robust network of RSBVs with gear-operated handwheels allows for manual isolation and backup control in the event of actuator failure. - Pre-Tested Modular Skid Design

Engineered for rapid deployment with minimal on-site assembly, allowing for scalable integration with existing infrastructure.

This project illustrates how SIT’s CDUs are built for scale, efficiency, and reliability, helping facilities meet both current and future cooling demands with confidence.

How CDUs Function in Data Centers:

Flow and Thermal Management

A CDU circulates coolant to heat-producing IT hardware and removes heat via a heat exchanger connected to the facility chilled water loop. This keeps coolant temperatures within tight tolerances and maintains optimal component performance.

Loop Isolation

CDUs separate the facility water from the IT loop, using a plate or coil heat exchanger. This prevents facility water contaminants from entering the IT loop while protecting against pressure shocks and oxygen ingress.

System Intelligence

Modern CDU systems include:

- Variable-speed pumps

- Redundant controls

- Digital interfaces

- Automated valve systems

- Sensor feedback loops

These enable predictive maintenance, remote diagnostics, and proactive thermal adjustments.

CDU Configuration Types

| CDU Type | Cooling Load Capacity | Ideal Use Case |

| In-Rack CDU | <30 kW per rack | Modular deployments, edge sites |

| Per-Row CDU | 100–200 kW | High-density rows, mid-scale environments |

| Centralized CDU | 500 kW to multi-MW | Hyperscale, cloud, and enterprise data centers |

SIT’s centralized CDU skid represents the high-end of this spectrum, supporting massive thermal loads while providing ease of maintenance, redundancy, and integration flexibility.

Why Choose SIT for CDU Solutions?

Proven Engineering Expertise

With deep domain knowledge in hydraulics, electromechanical integration, and fluid system design, SIT delivers solutions that exceed industry standards for uptime and thermal control.

Vendor-Agnostic System Integration

SIT’s solutions are compatible with leading technologies like Danfoss Drives, Editron Motors, and custom PLC control platforms.

Fast Deployment & Long-Term Support

CDUs are delivered pre-tested and fully assembled, reducing installation time. SIT also offers field service, commissioning, and ongoing technical support.

Built for Mission-Critical Performance

Designed with redundant pathways, manual overrides, and fail-safe mechanisms, SIT CDUs support data center environments where downtime is not an option.

Environmental & Operational Advantages of SIT CDU Systems

- Energy-Efficient Drives & Motors

Danfoss Drives and Editron motors reduce energy usage while optimizing performance. - Modular Redundancy

Dual pumps and manual backups safeguard against single-point failures. - Reduced Downtime Risk

Predictive diagnostics and modular design simplify servicing and minimize interruption. - Optimized for Sustainability

SIT CDUs contribute to lower carbon footprints and improved PUE metrics by supporting free cooling and reducing reliance on CRAC units.

Final Thoughts

SIT’s leadership in engineered cooling solutions is setting new benchmarks for liquid-cooled data center performance. As the digital economy expands and thermal demands intensify, SIT’s advanced CDU systems provide the scalable, efficient, and resilient infrastructure that future-ready facilities require.

From hyperscale operators to enterprise environments embracing AI, SIT stands ready to deliver reliable, precision cooling — engineered for performance, built for uptime. Contact us to learn more or get started with your next project.