When it comes to marine operations, ensuring the safe deployment and recovery of underwater vehicles and equipment is paramount. This task often becomes more complex in offshore settings, where precise and reliable systems are required to handle a variety of vehicles like remotely operated vehicles (ROVs), autonomous underwater vehicles (AUVs), and subsea drills. The Moon Pool Launch and Recovery System (MLARS) is a specialized system that addresses these challenges, enabling marine vessels to deploy and retrieve equipment through a moon pool — an opening in the hull of a ship that allows vehicles to be lowered into the sea.

Supreme Integrated Technology, Inc. (SIT), a subsidiary of Employee-Owned Holdings, Inc., has made impressive strides in developing custom MLARS structures to meet the demanding needs of marine exploration and subsea operations. One notable project involved designing a custom MLARS specifically for the deployment of an AUV. In this post, we will delve into the specifics of this innovative system, how it operates, the challenges it overcame, and why it’s a critical tool in offshore operations.

What is MLARS?

At its core, the Moon Pool Launch and Recovery System (MLARS) is a mechanism that allows for the controlled deployment and retrieval of marine vehicles or equipment through the moon pool. This process ensures that equipment can be safely and efficiently handled, even in challenging offshore environments. MLARS is crucial for operations involving ROVs, AUVs, and other subsea tools, as it minimizes risks during deployment and retrieval, even when a vessel is in motion or operating in harsh sea conditions.

Typically, the MLARS is customized for the specific needs of the vessel and the equipment it handles. This ensures that the system operates smoothly within the physical and operational constraints of the ship and can withstand the mechanical stresses encountered during deep-sea missions.

The Challenge: Designing a Custom MLARS for AUV Deployment

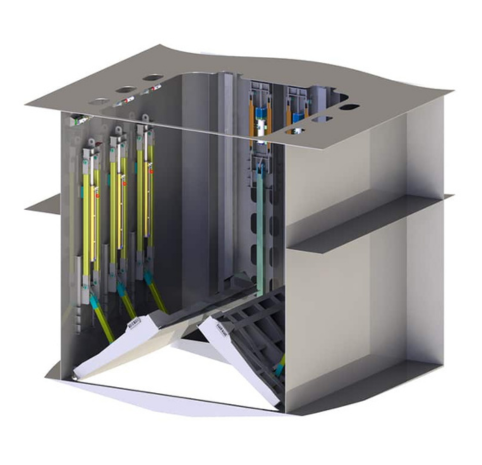

One of SIT’s significant achievements was designing a Custom MLARS for the deployment of an AUV from beneath a vessel through a moon pool. This task presented unique challenges that required a highly tailored approach, particularly given the stringent requirements for space, load handling, and operational precision.

The design of this custom system had to take into account several factors:

- Space Constraints: The system needed to fit within a tight space on the vessel while still being able to handle the heavy loads associated with the AUV and its equipment.

- Load Requirements: The system had to meet specific working load limits to ensure it could safely deploy and retrieve the AUV.

- Cable Management: The deployment process required spooling and managing 400 feet of cable, which necessitated a reliable and efficient mechanical level wind.

- Power Backup: The system needed to have a rescue winch and electronic clutch packs in place to safeguard the operation in case of a partial or complete power loss.

- Tilt Mechanism: The AUV had to be tilted at a 45-degree angle to clear the ship’s hull before being repositioned horizontally for deployment. This involved synchronizing multiple winches and mechanical movements to ensure precise handling.

In meeting these requirements, SIT had to combine its hydraulic and electrical engineering expertise to create a robust and adaptable solution.

Key Components and Innovations

The Custom MLARS designed by SIT featured several key components and innovations to address the specific requirements of the project.

- Moon Pool Door Launch and Retrieval: One of the primary objectives was to ensure that the AUV could be launched and retrieved through the moon pool doors safely and efficiently. This required a sophisticated deployment system that could guide the AUV through the pool without causing damage to the vehicle or the vessel.

- Winches and Mechanical Level Wind: A total of six custom winches were designed for the system. Four of these winches were synchronized in pairs, both mechanically and electronically, to ensure precise control over the AUV’s movement. One winch was responsible for managing the AUV’s umbilical data cable, while another rescue winch was included as a fail-safe in case of power failure. The mechanical level wind system played a critical role in ensuring the proper spooling of 400 feet of cable, preventing tangling or mechanical failure during operation.

- Tilt and Positioning System: One of the most challenging aspects of the design was developing a tilt system that would allow the AUV to be angled at 45 degrees to clear the ship’s hull. Once clear, the system would then tilt the AUV back to a horizontal position for deployment. This required precise coordination between the winches and a custom-designed trolley mechanism that could move fore and aft along the vessel’s deck.

- Control System: The entire MLARS was controlled via a fully integrated electrohydraulic system, operated through a Human-Machine Interface (HMI) screen located on the ship’s deck. This control panel provided the operators with real-time data and control over the system, ensuring that every movement was precise and safe. The joystick and touchscreen interface simplified the operation, allowing for easy adjustments and monitoring during deployment and retrieval.

- Rescue Winch and Power Failure Safeguards: To ensure the system could still operate in the event of a power failure, SIT incorporated a rescue winch along with electronic clutch packs. This redundancy was vital for ensuring that the AUV could be retrieved safely even if the main power system failed.

Adherence to Safety and Regulatory Standards

Safety and compliance with regulatory standards are critical in the design and implementation of marine systems. For this custom MLARS, SIT ensured that the entire system met the ABS (American Bureau of Shipping) Rules for Underwater Vehicles, Systems, and Hyperbaric Facilities. These regulations are crucial for ensuring that the system is safe, reliable, and capable of handling the rigorous demands of underwater operations.

Achieving Success: Fabrication and Assembly

Working with the specific criteria of the AUV cage and the existing ship structure, SIT fabricated and assembled a cursor assembly guide. This guide was essential for keeping the AUV stable and in position while it was being lowered through the moon pool doors. The fabrication process involved precision engineering to ensure that all components fit within the tight space constraints of the vessel, while still providing the necessary strength and durability for offshore operations.

Once the system was fabricated and assembled, extensive testing and fine-tuning were conducted to ensure that the system met all operational requirements. This included load testing, synchronization of the winches, and testing of the tilt mechanism to ensure smooth and reliable operation.

The Impact of SIT’s Custom MLARS

The successful completion of this custom MLARS project showcases SIT’s ability to innovate and develop systems that meet the specific needs of marine operations. The combination of hydraulic and electrical engineering expertise, coupled with a deep understanding of the challenges associated with underwater deployments, allowed SIT to create a system that was not only functional but also efficient and reliable.

This custom MLARS is now a critical tool for AUV deployment in offshore operations, ensuring that vehicles can be launched and retrieved safely and efficiently, even in challenging conditions. The system’s compact design, precise control mechanisms, and built-in safety features make it a standout solution for subsea operations.

Conclusion

Supreme Integrated Technology, Inc. has demonstrated its ability to develop custom solutions that address the complex needs of marine and offshore industries. The Custom MLARS project for AUV deployment exemplifies how innovation, engineering expertise, and attention to detail can come together to create systems that enhance operational efficiency and safety. Whether it’s the development of custom winches, specialized control systems, or the integration of advanced safety features, SIT continues to be a leader in the design and implementation of marine technologies.

If you’re interested in learning more about SIT’s MLARS systems or have a specific project in mind, the company is available to assist. Their team of experts is well-equipped to handle large movable structures and other marine-related challenges.

For more information about Supreme Integrated Technology, Inc. and its employee-owned company structure, visit their official website at www.supremeintegratedtechnology.com.